PERIPHERAL

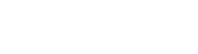

CPF-05

Self-leaning function by means of integrated micro computer will feed a wire to the machine neatly. It controls the slack of wire and unique wire straightener improves the products quality. Furthermore, the great value of the processing and high work efficiency are realized by high speed wire feeding performance (Max. speed 3.3m/sec.)

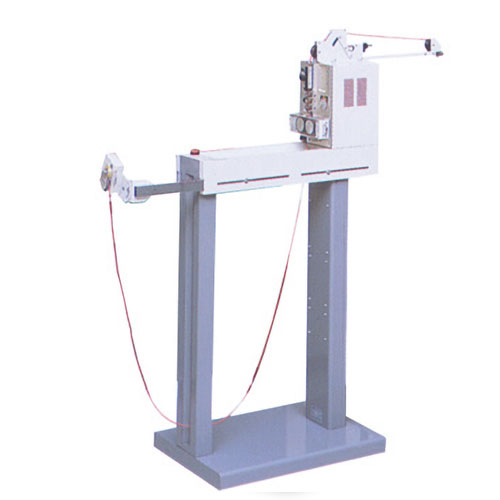

CAS OP-7

Holding from inside the winded wire prevents it from breaking. Of course you can set the wire with its tray. With the rotation sensor, the wire is rotated as much as it is unwound (fed) from the winded wire.

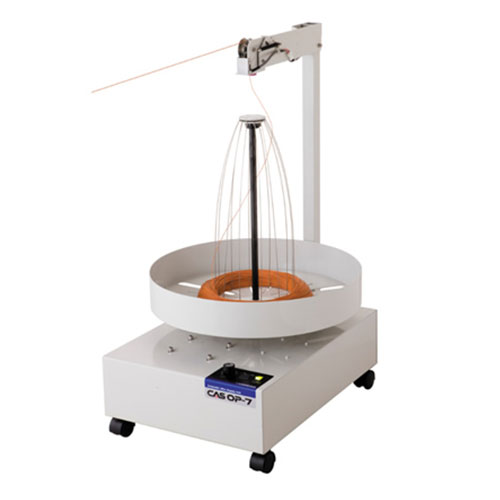

CPD-06

The unit supplies the wire while straightening the wire from the bobbin. The speed is controlled automatically, so that smooth supply is ensured.

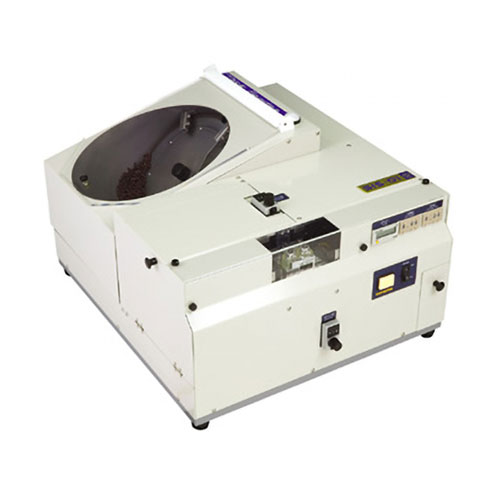

CCP-02

Appearance from the head unit of “CASTUGNON C511”Crimp Force Monitor is installed, which can strictly monitor to the every crimping by the load cell on the ram of crimping machine. With “shot counter” and “rejected goods selector”.

SIS - 01

This high technology machine can insert a seal and strip accurately the inner wire of multiple core cable, etc.. This machine installed “DF-01”, which is well-established disk feeder for CASTUGNON Series, and provides speedy and stable sealing. Using with semi-auto crimping machine “CCP-02”, the integrated processing from sealing to crimping can be arranged.

OR-01

This is originally developed for the proper oil removal for the seal. One touch oil removal, which used to be done manually. KODERA realized the user’s needs for the sealing. ( Patented product )